Brand Story

Rotonda a Mare is a well-known tourist attraction in Italy, drawing numerous visitors with its unique coastal scenery and rich travel experiences. To enhance the tourist experience and promote the scenic spot's brand image, it planned to launch custom tote bags for tourists to use or keep as souvenirs. It had strict requirements on the quality, design, and production cycle of the tote bags, and expected to find a professional and reliable OEM factory to create high-quality custom products that align with the scenic spot's positioning, further strengthening tourists' affection and memory of the scenic spot.

Brand Goals

Offer tourists practical tote bags with the scenic spot's unique features to improve their travel experience; Disseminate the scenic spot's brand via custom tote bags to increase its reputation and influence; Guarantee the high-quality delivery of 5,000 tote bags within 30 days to satisfy the scenic spot's operational requirements.

Solutions

Professional Customization, Efficient Delivery

In response to Rotonda a Mare's customization needs, Gahumi first accurately grasped the product requirements and quickly launched the sampling work. Relying on rich production experience and professional technology, the sample testing passed the customer's confirmation in one go, saving time costs.

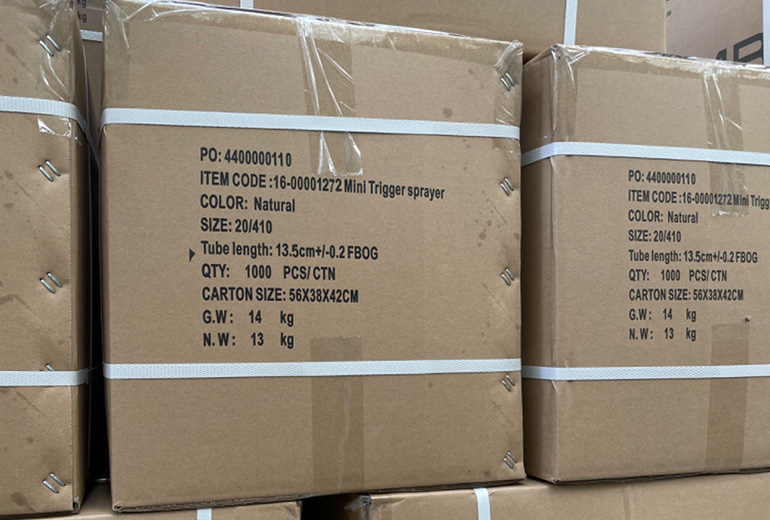

Considering the customer's emphasis on packaging, Gahumi proactively provided 3 different packaging methods to fully meet the customer's diverse needs and ultimately helped the customer select the optimal solution. During the production process, Gahumi formulated a detailed production plan and timely shared process photos with the customer, allowing the customer to keep track of the production progress in real time and eliminating their concerns. Meanwhile, facing challenges such as the time-consuming customization of auxiliary materials, high requirements for sewing technology, and the need for consistent printing colors, Gahumi quickly found suitable suppliers to secure the auxiliary materials, strictly controlled the sewing and printing links to ensure product quality, and finally completed the production of 5,000 tote bags within 30 days.

🚩About the Customer

As a popular tourist attraction in Italy, Rotonda a Mare enjoys high popularity in both the local and international tourism markets. It is committed to creating a high-quality tourism environment for tourists and constantly explores ways to improve the tourist experience. This customization of tote bags is an important measure for its brand promotion and tourist service optimization, reflecting the scenic spot's pursuit of details and quality, as well as its strategic plan to actively expand brand influence.

🚩About Gahumi

Founded in 1994, Gahumi is a comprehensive fabric-printing enterprise integrated with product R&D, design, manufacture and sales. We offer a full line of fabric-printing, including towel, golf towel, flag, advertising T Shirt, sports activities item, fans scarf, hats caps, and other election accessories etc.

Based on 31 years' manufacturing experience, we have been exporting products to US, Europe, East Asia, Africa and Middle East. And we have set up long-term partnerships with companies from all over the world.

Our clients benefit from lower manufacturing costs and time-to-market volume production through over 300 highly qualified staffs and 3 manufacturing facilities, with a total 5000 sqm factory, including raw material center, sewing center, full-auto printing center, and assembling center. We provide OEM/ODM/Private label/Wholesale services to global brands.

The Solution

Display finished sample T - shirts of different techniques to enable customers to make intuitive comparisons.

Cooperating with Gahumi to customize 5,000 tote bags was an extremely correct decision. From sampling to delivery, Gahumi was professional and efficient. The sample passed our expectations in one test, and they also provided 3 packaging solutions. During the production process, they timely shared the production plan and photos, which put our minds at ease. The 5,000 tote bags were delivered on time within 30 days, and the products passed the full inspection and third-party inspection with excellent quality, greatly contributing to the promotion of our brand.

FOR CUSTOM YOUR BRAND

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap